In manufacturing units especially involved in the manufacturing of food, beverage, pharmaceuticals, and other similar products, a filling machine, which is, in other words, a kind of packing machine that can dependably fill a large volume of suitable containers with particular ingredients to a desired level, is a mandatory undertaking. While discussing filling machines, numerous kinds of filling machines are available. Based on the necessities of the manufacturing unit, which is best suited to meet the needs. The right filling machine must be chosen that can significantly improve the production rate and passively contribute to meeting market demands, thereby boosting sales and enabling the business to grow towards progress. While filling machines are basically classified according to their applications, like powders, liquids, granules, and pastes, filling machines that are used to fill larger containers are usually referred to as drum filling machines. Liquid Filling Machines are normally used in the soft drink and fruit juice manufacturing industries to dispense the desired quantity of the relevant liquid product into suitable bottles, cans, and cups that are capped. These machines are hence used to fill liquids, such as water, various kinds of beverages, carbonated drinks, sauces, and much more. Liquid filling machines are further classified as manual, automatic, and semi-automatic liquid filling machine varieties; they are quite versatile in performance.

While in-line liquid filling equipment fill containers that are placed and supplied in a line through conveyor systems, rotary filling machines are supplied for filling in circular stations and are used to fill bottles, where each station is set to perform a specific function like filling and capping. Piston fillers are used in cases where accuracy is required in pouring liquids into specific containers in a specific quantity, and hence they are used to fill liquid soaps and semi-liquid food products like sauces. Another type of filling machine is the powder filling machine; these fillers are designed and developed in such a way that they are enabled with a complex mechanism that ensures accuracy in their operation. Appropriate for filling free-flowing powdered products, these machines are most suitable for filling talcum powder, certain types of medicines used for external application and dusting, powdered beverages, and more.

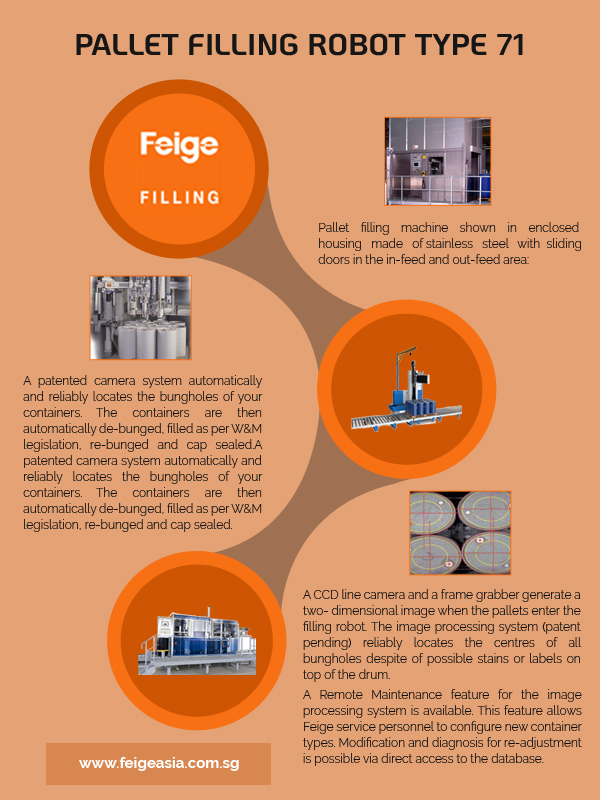

Feige Filling is one of the leading manufacturers of filling machines, known for its high speed performance and accuracy. The company is also well known for providing fillers required to fill large pails, drums, and similar containers. Apart from this, Feige Asia has a consistent reputation for dealing with, supplying, and servicing filling machines that include vibratory weigh filling machines, capsule filling machines, and positive displacement pump filling machines that are widely in need in different sectors like the food and pharmaceutical industries.

Recent Comments