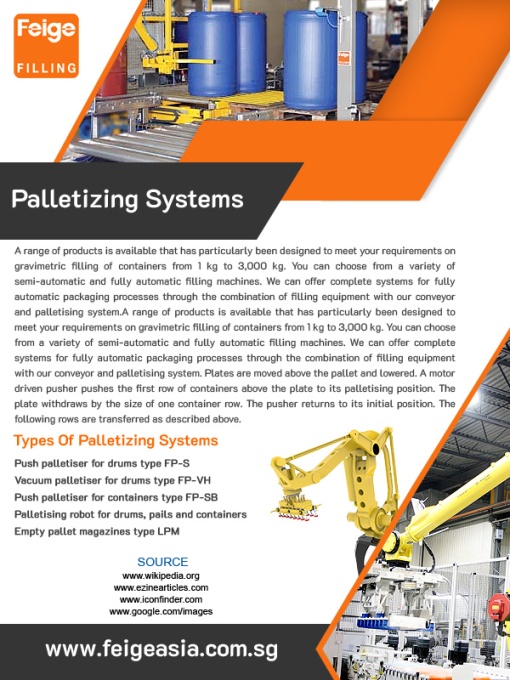

A palletiser is a mechanical device that allows the automation of placing items on top of a pallet. It dramatically reduces the amount of time involved compared to stacking the items on the pallets by manual labour. It is also much safer using these palletisers than using human workers to transfer any heavy items by hand, reducing the workplace accidents or injuries.

Feige Filling Technology Pte Ltd Offers a range of palletizing systems such as the push palletiser for drums and containers, vacuum palletiser for drums, palletising robot and the empty pallet magazine.For the push palletiser for containers, two containers are first placed on top of each other in two rows. These will be pushed by the palletiser onto the pallet. For the vacuum palletiser for drums, it is suitable for any containers with smooth tops.

Plastic drums that are built with stable tops can also be used. Its advantage is its compact design which can deliver up to 70 pallets in an hour with a total of 4 drums placed 2 by 2 in one pallet. The vacuum palletiser contains devices called gripper to pick up the drums and put them safely on the pallets. The empty pallet magazines are designed to store up to 15 pallets without cargo.

These magazines dispense the bottom pallet onto the conveyor system so that the cargo can be stacked on it at the next stage. The LPM-2 model is able to manage 2 way and 4 way pallets while the LPM-4 is able to manage 4 way pallets. The manipulators are equipped with a carefully crafted gripping device to lift the containers and put them down on a pallet. Staff can be trained to use the manipulators ergonomically and safely, leading to a better efficiency in terms of both cost and time.

Palletising robots are used to automate the loading and unloading of goods onto pallets with a high level of consistency. It is one of the most favourable options available to achieve the best effectiveness in terms of cost and time when various distinct types of containers and pallets are required to be manipulated.

The palletising robot type IRP4-160-2.9 is a four-axes robot that can manipulate items up to one hundred kilograms.

It is able to reach a distance of up to 2.9 meters with a given output of 450 working cycles in an hour. Its four axes can be upgraded to six axes if more complex movements are required. The Palletising robot type IRP6-420-2.8 is a higher end model consisting of six axes that can manipulate items up to three hundred kilograms. It is able to reach a distance of up to 2.8 meters.

It is able to achieve an output of 450 working cycles in an hour. However, this rate is lowered when the load is increased near to its maximum capability of three hundred kilograms.For additional safety compliance, fences can be erected around the palletising system to protect staff from accidentally injured by the operations of the moving mechanical components.

In Order To Find Out More Details On Palletizing System Please Be Touch With Us Today Onwards..!

Recent Comments