It is a general fact that fillers or technically known as filling machines are those equipment or machinery that is used in the packaging, especially in the food and beverage sector. Packers, fillers or filling machines are essential in filling and packing of finished products in other sectors as well. Although the filling machine is significant machinery in almost all the food product manufacturing industries, they play a vital role in the pharmaceutical industry. Since the pharmaceutical industry is totally dependent on the filling machines, it is in a way an indispensable device. Be it a syrup, cream or paste filling machines are employed in every case. This apart the parenteral medicines like injections need special kids of fillers that are called ampule filling machines, and are mandatory machinery in every pharmaceutical unit, that manufactures injections, u v fluids and similar products.

The type of pharmaceutical product determines the particular filling machine that is to be used. The product to be filled, swiftness, quality to be maintained, shelf life, technical feasibility and other aspects. The first type of filling machine is the flow filler, specifically designed and developed for filling liquids and oil based products. While these kinds of Liquid Filling Equipment fill the bottles both big and small, and open up on the conveyors for sealing and are most suitable for syrups, and less viscous liquid pharmaceutical preparations. Another significant filling machine used in this sector is the tablet filler, designed for tablet filling in which the fillers count the number of pieces and fill them accordingly into bottles. Pump filling machines are important fillers that are used to for filling lotions, creams, gels and other heavy paste products. This filling machine also can fill creams, sauces, shampoo, conditioners, and so on.

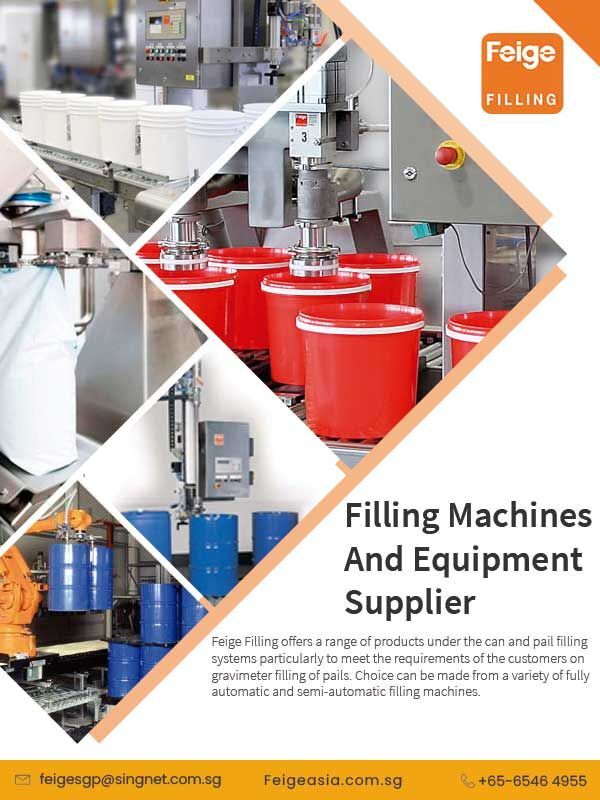

The next type of fillers that are exceptionally important in a pharmaceutical industry is the vial fillers, which are basically cost-effective for the reason that they perform efficiently, in a comparatively less space, and requires a single operator. These fillers comprise of sensors that enables that the quantity in every vial will be the same thereby optimizing productivity. As a matter of fact vial filling machines offer a cost-effective, performance and efficient device for vial filling. Organizations like Feige filling, a leading manufacturer of filling machines for liquid and pasty products, hold a reputation of being a global manufacturer of filling machines. Feige filling are known for high level of speediness, dependability and accuracy in gravimetric filling. They offer various kinds of filling machines, for filling liquid and pasty products into containers such as pail filling, can filling, drum filling etc.

Recent Comments